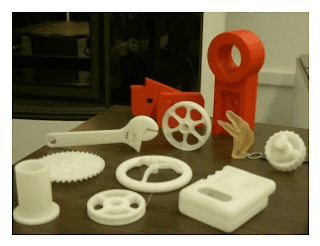

Rapid Prototyping (RP) can be defined as the methods used to create the model scale (prototype) of the starting part of a product (part) or assembled product (assembly) quickly by using data of Computer Aided Design (CAD) three dimensions. Rapid Prototyping allows the visualization of a three-dimensional images become three-dimensional objects that have the original volume. In addition rapid prototyping products can also be used to test a specific part. Method of RP first discovered in 1986 in California, USA by Stereolithography method. After the discovery of these methods evolved a variety of other methods that allow the creation of a prototype can be done quickly.

|

| Rapid Prototyping (RP) |

Currently, prototyping becomes its own terms on some companies in the refinement of its products. Some of the reasons why rapid prototyping is very useful and necessary in the industrialized world are:

Improve the effectiveness of communication in industrial environments or with consumers.

Reduce production errors which resulted in membengkaknya the production cost.

Reduce product development time.

Minimizing any fundamental changes.

Extending the period of use of the product for example by adding some features or components reduces the features that are not needed in the design.

Rapid Prototyping reduces product development time by providing opportunities for correction in advance of product made (prototype). With prototype, engineers can analyse corrects some errors or discrepancies in the design or provide touches of engineering in the refinement of its products. The current trend that is developing in the industrialized world is the development of a variety of products, an increase in the complexity of the product, the product of age wear a short, and a decline in production costs and delivery time. Rapid prototyping improves product development with more effective communications enable it in the environment industry.

A few Rapid Prototyping methods are evolving right now are:

- Stereolithography (SLA)

- Selective Laser Sintering (SLS)

- Laminated Object Manufacturing (LOM)

- Depsition Fused Modelling (FDM)

- Solid Ground Curing (SGC)

For an explanation of each coming soon Yes:). This is part of CHAPTER II of my thesis about lho Machine Fused Deposition Modelling (FDM) is one of the methods above RP. If the hearing of my thesis done, I jelasin one by one. Soalnya emang susah cari which Indonesian Language (easier to understand). Hopefully useful.